Introduction

Renewable sources of energy (green energy) are currently the main focus of the research of engineers.

It is now a common belief that our planet has finite resources and that we must act thinking about the future of the new generations. Primary objectives must be energy-saving and the limitation of polluting emissions.

The efficiency of the Wind and Solar photovoltaic systems is a crucial aspect to realize robust, safe, and long-lasting solutions. And the good cooling of the inverters is, once again, the “secret” of success.

Priatherm’s team has been at the forefront of developing cooling solutions dedicated to this world for years.

Application field

- the compactness of the heat sink

- its efficiency (including the possibility of using quiet ventilation) and, in particular,

- its cost-benefit ratio

The challenge

The customer’s goal was to push on the market a three-phase string inverter with the following characteristics:

- Max efficiency

- High robustness and flexibility

- Easy installation

- Safe

- Smart

- Remote control and maintenance

The choice of the heatsink was by no means trivial due to the competitive cost specifications, small size, and flexibility in increasing performance without additional investments in production equipment.

Solution

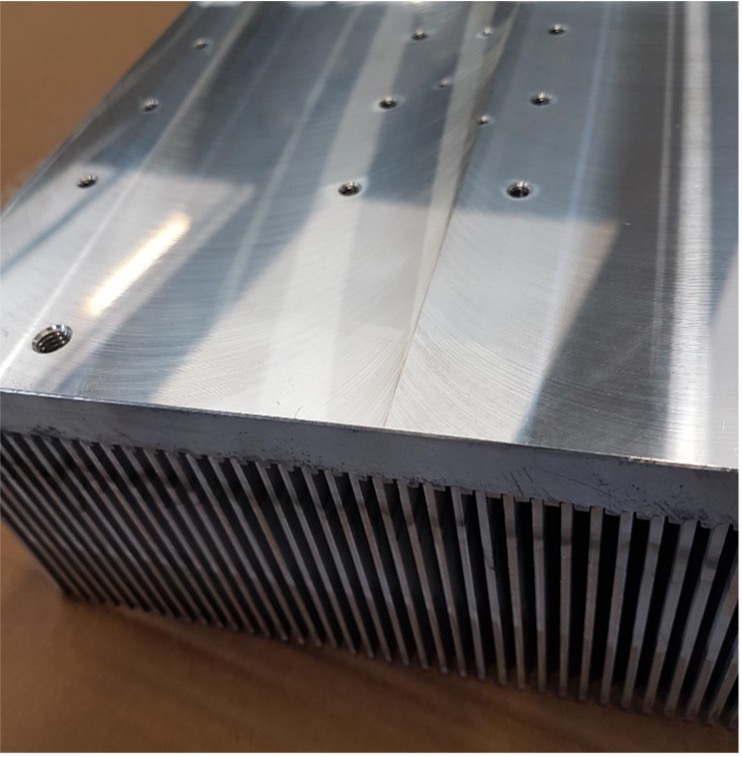

- Initially with a compact Brazed fin (PT High) – 225x300x100 mm, with 44 fins – 3000 W have been dissipated. Three heatsinks in parallel were able to realize one of the most competitive solar solutions in the world. The customer was able to win tenders in North Africa, Central America, and South America.

- Later, the customer decided to make an upgrade of its machine and brought the Power to dissipate to 4000 W per module.

- High-performing heatsink: given the metal joint between base and fins, no air gap, no barriers to thermal conductivity

- Compact design: thanks to the high fin ratio, not achievable with the standard extrusion process

- Cost-effective: with a simple design, fast to assembly

Top challenges

- High performance vs compact dimensions

- Researching a solution with the best ratio “benefit vs cost”

- Scalability of the design (increasing power) without additional tooling costs

Ask our Experts

Error: Contact form not found.