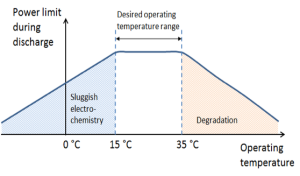

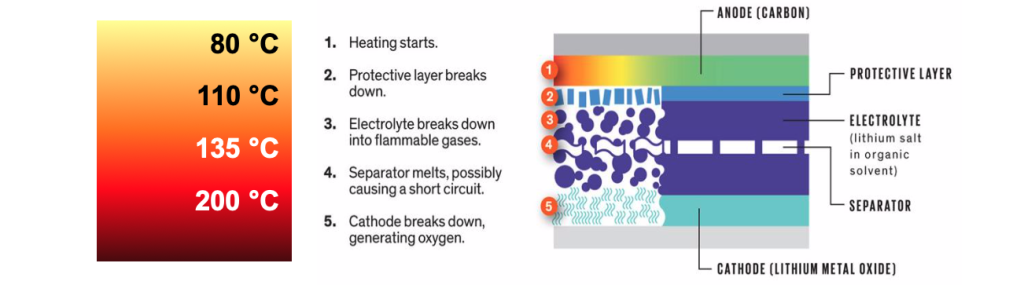

Temperature is one of the most critical factors in designing and operating HEVs. An extremely high temperature may lead to explosion through thermal runaway or performance degradation of battery cells. Onthe opposite end, a battery system operating at low temperature might be dysfunctional. To address the challenges related to temperature, most automotive manufacturers have developed their own thermal management systems for their EVs in order to trigger the thermal control when temperature deviates from the normal operational range. This control includes usually both cooling and heating.

Temperature is one of the most critical factors in designing and operating HEVs. An extremely high temperature may lead to explosion through thermal runaway or performance degradation of battery cells. Onthe opposite end, a battery system operating at low temperature might be dysfunctional. To address the challenges related to temperature, most automotive manufacturers have developed their own thermal management systems for their EVs in order to trigger the thermal control when temperature deviates from the normal operational range. This control includes usually both cooling and heating.

How is heat generated by a Li-ion battery?

How is heat generated by a Li-ion battery?

Heat in a battery cell is generated by two main factors:

Heat in a battery cell is generated by two main factors:

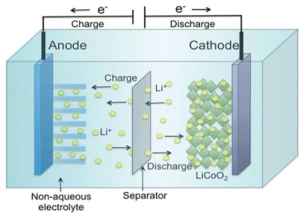

1 – Joule effect from internal resistance of various cell components (electrode, cathode, anode…). It can be minimized by cycling cells at low currents.

2- Exothermal electrochemical reactions within the cell that cause the transfer of ions.

What happens in the battery when temperature increases out of control?

How can a battery cell’s temperature be kept under control?

The first way to ensure batteries work in an optimized condition consists of a well-designed Battery Management System (BMS) that not only protects the cell against overheating but also optimizes its efficiency and monitors its charge (SOC) and “health” (SOH).

Battery cooling

The BMS alone is in most cases not sufficient to ensure efficient working conditions for a Li-ion battery.

Batteries have to be cooled down through air flow or through putting them in contact with liquid coolers. As such, there are basically two common battery thermal management methods:

- Air convection, either passive or forced.

- Circulation of water-based coolant through liquid coolers within the battery structure.

- Air cooling

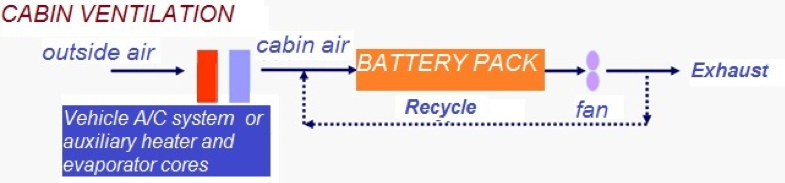

Fresh air that flows through the battery cells comes usually from the cockpit, which is conditioned by the A/C car system.

This method has its own pros and cons, shown in the table below.

| PRO | CON |

| Wasted heat goes eventually to outside air | Lower heat transfer capacity |

| Separate cooling loop not required | Higher temperature gradient within the battery |

| No risk of leakage | Potential backflow of venting battery gas into cabin |

| No risk of electrical short due to fluid concern | Fan noise |

| Less system complexity (lower cost) | |

| Easier maintenance |

Examples of hybrid and electric cars where the battery is cooled by air are the Toyota Prius (NiMH cells) and Nissan Leaf (Li-ions cells).

- Liquid cooling

Although air as a heat transfer medium is a simple option compared to liquid, the thermal properties of liquids enable them to remove more heat than air when being used as a cooling medium. Therefore, they are used in applications where large amounts of power or a high thermal density needs to be removed from the batteries.

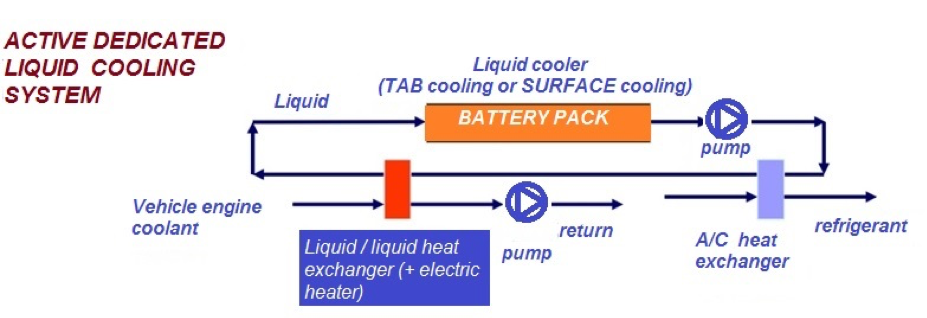

Fluid is cooled down by the A/C car system or, more often, by a dedicated liquid /liquid cooling unit.

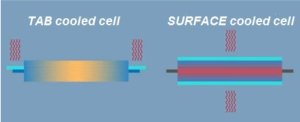

Pouch-shaped cells are usually cooled by liquid coolers that are directly in contact with their external surfaces, taking advantage of their large areas. However, recent studies show that this could lead to a significant loss of performance and increased loss of useable capacity under load.

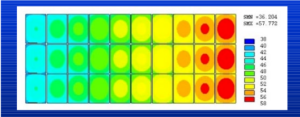

For this reason, tab cooling seems to be more efficient in terms of temperature gradient. That means:

- Higher cell efficiency

- Less risk of thermal crack after several load/unload cycles

Below is a table with general pros and cons of liquid cooling systems for electric and hybrid vehicles.

| PRO | CON |

| Higher power flux absorption | Additional components |

| More uniform thermal gradient amongst cells | Weight |

| Lower volume, compact design | Potential risk of leakage |

| Better thermal control (T fluid IN more constant) | Higher maintenance costs |

| Fluid pre-heat necessary below 0°C |

Examples of hybrid and electric cars where the battery is cooled by fluids are the Tesla-S and Audi A3 Sportback e-tron.

Input Data for Battery Thermal Management of Hybrid and Electric Cars

Generally speaking, in order to design properly a battery cooling system for EVs or HEVs, the following info has to be available:

- Cell shape: prismatic, pouch, cylindrical

- Weight constraints and battery location

- Cooling media available on board

- Inlet fluid temperature

- Thermal interface materials

- Surface vs. tab cooling

From 2020 onwards, the utilization of conventional thermal engines is expected to decrease, and it will have disappeared by 2050. Lithium-ion batteries represent at the moment the most prevalent storage device in EVs and HEVs, and their study is attracting more and more interest.

A well-designed temperature regulation system for batteries is a basic requirement to get efficiency from electrical engines. Keeping the temperature within the desired range and low temperature gradients can guarantee a longer battery lifetime and better energy efficiency. Thermal management topics have to be investigated by a team of experts from the earlier stages of the design process.

Click on the picture and download our free e-book

“Four Common Mistakes To Avoid When Selecting a Heat Sink”