Introduction

With this case study, we would like to describe a particular project we carried out at the beginning of 2020, related to an Electric Supercar liquid cold plate for battery cooling.

Electric cars are one of the hottest topics right now, and that’s why Priatherm is focusing its R&D on the development of the most efficient cooling solution. To guarantee great performance, battery thermal management is one of the most complex issues this sector is facing.

Instead of going too deep into technical details, we want to underline how our core technology, the brazing technology, allowed us to smartly think the heat sink design, based on the initial idea our customer had, to optimize it in terms of:

– Performance

– Costs

– Design

Our Customer: InMotion

InMotion is a team consisting of more than 50 students from the Eindhoven University of technology and the Fontys University of Applied Sciences.

Located in Brainport Eindhoven, a region where 40% of all the Dutch R&D activities take place and major companies are rooted, the team represents a unique collaboration between the academic and the industrial world.

The mission of InMotion consists precisely in making the recharging of electric cars as fast as refueling petrol or diesel cars. It is well known that one of the reasons holding back the spread of electric cars is the long charging times.

This mission requires an efficient cooling system, both for the car itself and for the charger, to maximize energy transfer efficiency, reducing heat loss as much as possible.

Besides, the battery pack must ensure the safety necessary for daily use.

The challenge

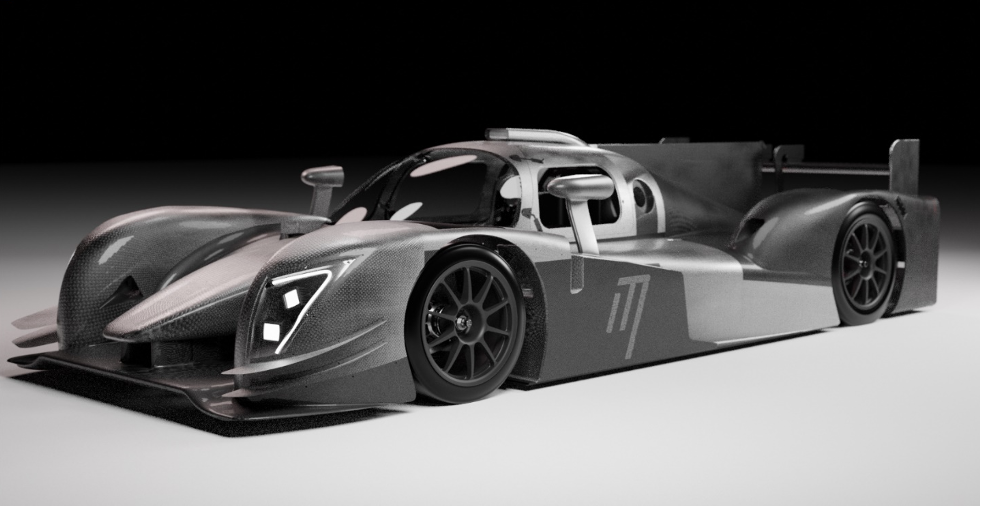

Following an initial meeting at a fair, InMotion contacted us for collaboration regarding the lithium battery cooling of their new project: a racing car participating in the 24h of Le Mans.

Garage 56 – the name of the Project- is a concept specifically related to the 24 Hours of Le Mans, to promote innovative automotive technology. The contender only has to comply with the safety regulations and does not have to meet strict technical rules.

This platform provides the opportunity to build the ultimate race car and showcase its innovative technologies. This is why InMotion aims to join the 24 Hours of Le Mans in 2023 with a fully electric endurance race car, an LMP3-based race car.

During fast charging, there is an exponential buildup of heat in the lithium-ion cells. The temperature in the cells needs to be regulated to stay in their optimum range, with a maximum of 45 degrees Celsius.

By using liquid cold plates on the module cooling interface this heat is transferred to the cooling liquid. Coupling this coolant system with a high-end refrigerant system, the battery temperature can be properly managed, even during Electric Refueling and racing at high speeds.

Despite the presence of different production methods for heat sinks and liquid cold plates, after a brief presentation of the several advantages that the brazing process has to offer, the InMotion team was firmly convinced to proceed with this kind of solution.

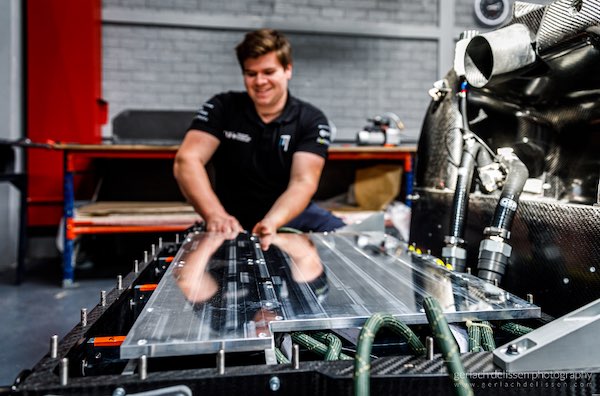

Once the 3D file was received, we opened it to discover a liquid cooling system for the entire Battery Pack, consisting of three smaller liquid cold plates, needed to cool the individual modules. These then rested on a much larger LCP, made up of complex internal circuits to be optimized together.

Solution

As expected, while for the three Liquid Cold Plates implementation we didn’t foresee particular issues, the big LCP, not reproducible with deep drilling or mechanical connections between parts, was going to be the major challenge.

One of the biggest advantages of Brazing technology is that there are practically no dimensional limits for the heat sink. This is the only limit: each unit must be placed inside our oven, so the maximum dimension per unit is 1300×700 mm and more units can be joined together at a later stage.

What we do when we create a Liquid Cold Plate is starting from an aluminum base where, through milling processing, channels are obtained. Through these channels then, the coolant (a mixture of water and glycol) will flow. An aluminum cover joined to the base through our aluminum brazing process allows you to seal the channels, creating a metal joint between the base and the cover.

The cooling plates have a complex routing of narrow channels to ensure optimum cooling performance, while all channels must be isolated from their neighboring channel. This meant that many manufacturing methods would not suffice. Think of welding, laser welding, friction stir welding, etcetera.

The LCPs are part of a liquid cooling system based on forced convection cooling, also composed of: a heat exchanger, a pump (which generates the movement of the fluid), and a tank, which stores the fluid. The liquid cold plate represents the component in direct contact with the heat source.

Therefore, a unique compound is obtained, which has considerable advantages:

- no o-ring is required, as the junction between the base and the cover is metallic;

- great flexibility in designing the channels, which can be placed directly below the heat sources;

- the connectors, if made of aluminum, can be directly brazed onto the plate;

- more compact and performing solution than an air cooler

In our case, starting from a single base, we brazed two covers onto it, mechanically joined together. In short, through smart thinking and designing, we were able to make the most out of our core technology within the size limits requested by the customer.

Although it all started from a predefined initial drawing, the dialogue with the InMotion team was always fruitful as ideas flowed smoothly and our heat sink design suggestions always found a good reception.

Top challenges

– The dimensions of the large Liquid Cold Plate: we had to find a solution that would allow us to meet the request, almost 800×600 mm, mixing our brazing technology with a mechanical joint of the cover

– The number of internal circuits: changes have been made to the initial design, reducing the number of internal circuits while maintaining the same performance

– The research and identification of the ideal connector: thanks to the collaboration between the two technical departments, we have identified a solution that would guarantee the best value for money

– Challenging tolerances: almost at the limit of compatibility with brazing technology. In this case, flatness was 0,03/100

Ask our Experts

Error: Contact form not found.