The geometric characteristics and the quality of the surfaces plays a crucial role in the functionality of a heat sink for electronic components.

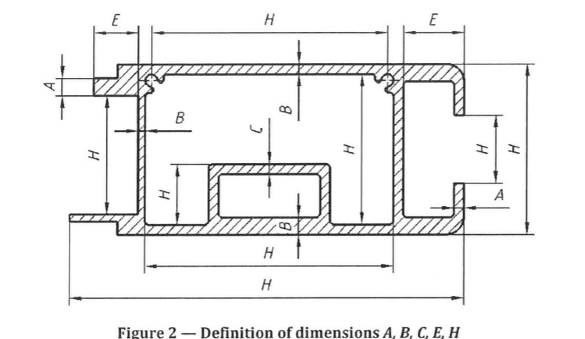

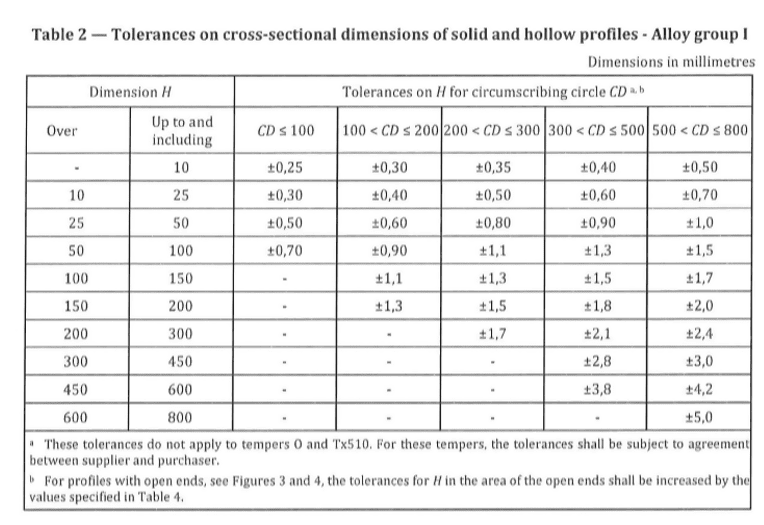

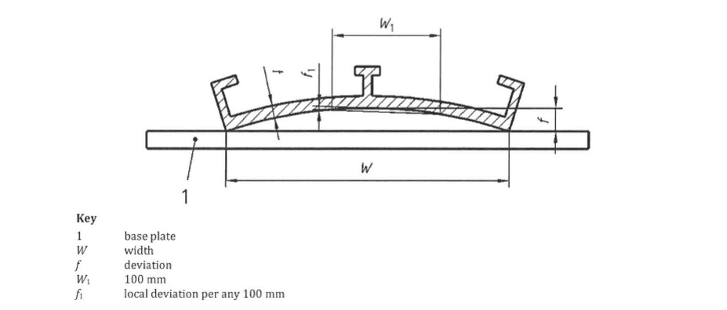

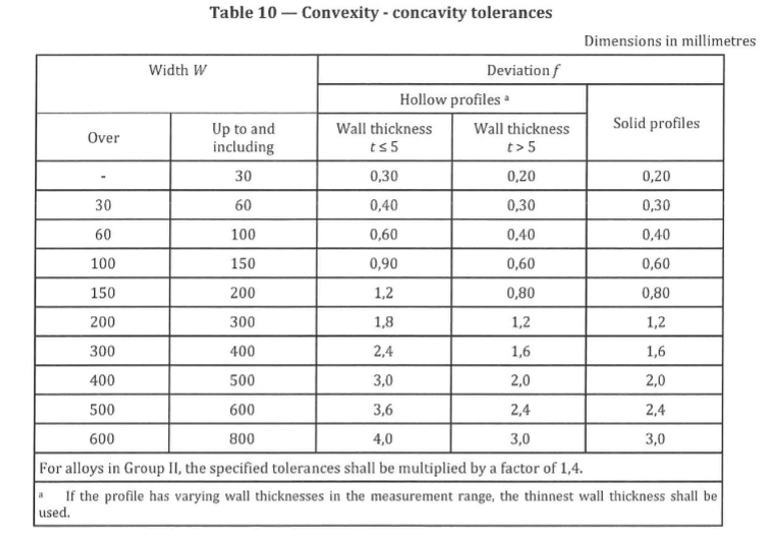

To produce heat sinks for low and medium powers extruded aluminum profiles are mostly used, these profiles have dimensional precision limits regulated by international standards. For example, UNI EN 755-9.

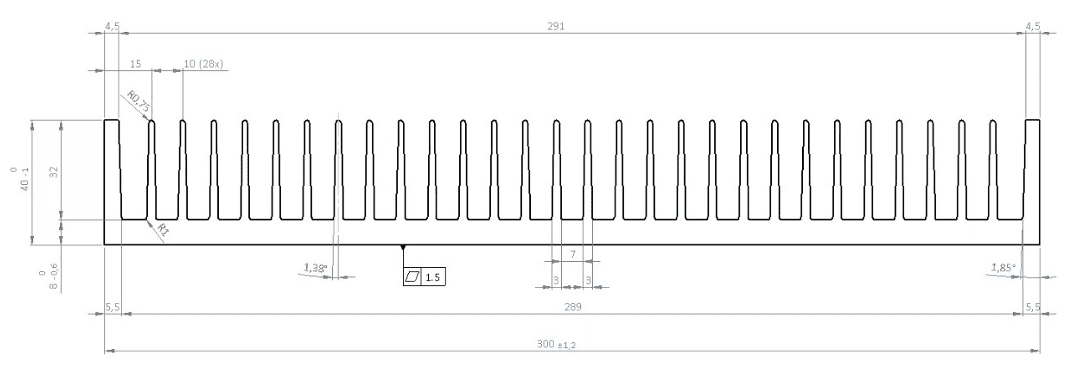

Often, the dimensional tolerances obtainable by extrusion are not sufficient to meet the technical specifications of the application. For example, the flatness and the roughness of the interface surfaces are too coarse for the couplings with the electronic components or the dimensions are not sufficiently precise for an appropriate assembly with carpentry or other components of the application.

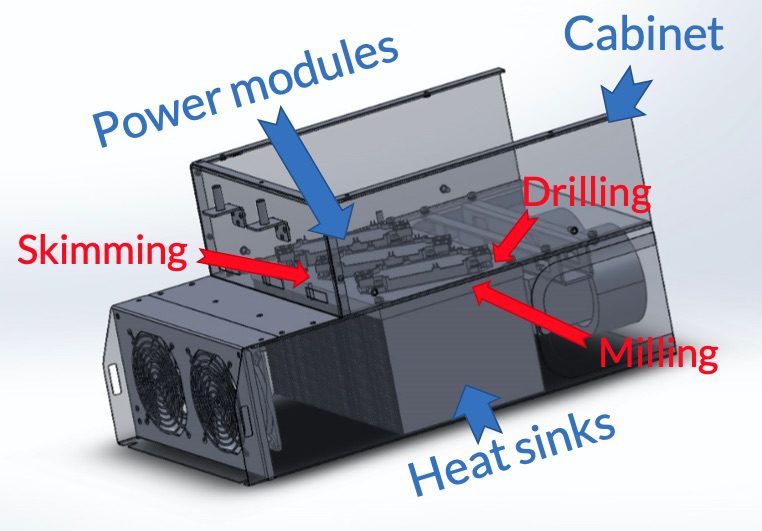

High power heat sinks are produced with different production processes: such as braze welding, assembled profiles, etc. Also, the semi-finished products have dimensional tolerances and surface’s quality not suitable to be used as it is.

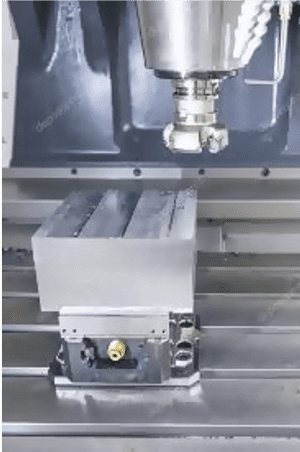

To reach the required characteristics, including possible drilling for mating to the heat sink, the electronic components, the carpentry or other accessories, the mechanical machining must be carried out, mostly using CN machining centres.

The machining is defined during the heat sink development phase and is based on user’s requests and the feasibility assessment carried out by the design team. The machining is specified in the production drawing together with the machining tolerances (deviation in a specific dimension within which it is possible to accept the heatsinks).

It’s good to keep in mind that both the functionality of the piece and its cost depend on the range of the tolerance with which the piece is to be worked: the tolerance set for the work should be restricted as much as necessary for the functionality of the piece, no more.

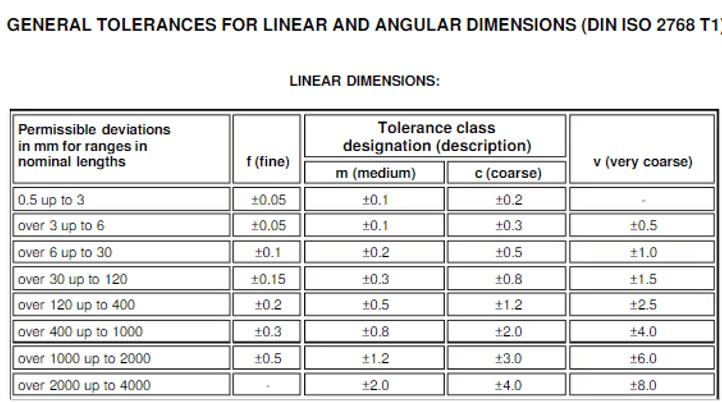

For all the dimensions where tolerance is not specified, the reference is normally the general tolerances defined by standards.

Priatherm applies the tolerances set by the UNI EN 22768-mK standard.

Quality of surfaces for modules.Characteristics guaranteed by Priatherm:

- Flatness: 0,03/100 mm

- Roughness: Ra < 0,8 µm

Our R&D team is available to support customer technically in the development phase by evaluating his needs and elaborating on the best proposal in terms of feasibility and costs.

Click on the picture and download our free e-book

“Four Common Mistakes To Avoid When Selecting a Heat Sink”